Aesthetic is not the only element that you should consider when you choose packaging for your cosmetic products; it’s an intricate balance between functionality, sustainability, reliability, and cost-effectiveness.

From navigating material choices to ensuring compatibility with the product, each step shapes the brand’s identity and consumer experience.

Here, we’ll share insights gleaned from years of experience and collaborative discussions with our clients.

Let’s explore critical factors and considerations that define the path from concept to shelf-ready product.

Packaging Regulations & Compliance – 1

Understanding packaging regulations and compliance is vital for brand managers, packaging purchasers, and designers. This knowledge not only elevates your professionalism but also shields you from market-related pitfalls and unnecessary expenses.

Packaging regulations encompass more than just design; they extend to packaging rules and recycling objectives that must be adhered to.

For example, in the UK, if you’ve manufactured or imported 10 or more tons of plastic packaging in the last 12 months, you may need to register for a specific tax. Additionally, Spain and Italy have recently implemented Plastic Taxes.

Packaging Compatibility – 2

Ensuring compatibility between your product and its packaging is crucial. Factors like viscosity, rheology, or the pH of your cosmetic formula directly influence the design and material selection for packaging.

Mismatched packaging and content can alter the appearance, scent, and formula efficacy, and even cause leakage. These negative user experiences can lead to dissatisfied customers and potential product liability.

To safeguard your brand and customers, rigorous compatibility testing is essential. Even with materials like glass, known for strong chemical stability and compatibility with most cosmetic ingredients, conducting thorough tests is crucial.

As a packaging supplier, we offer customers guidance on selecting the right packaging materials for their products, and we believe this is a fundamental step in helping customers create great products.

Consider User Experience – 3

When considering user experience, it is crucial to prioritize the ease of opening and/or resealing the packaging. Should lotions or toners be dispensed through pumps or droppers? Are creams, scrubs, or gels more practical and mess-free when packaged in tubes rather than jars? These are the questions you should ask before choosing the right packaging.

Furthermore, conducting thorough research to understand customers’ pain points while using similar products can guide you in choosing packaging with the right style. By addressing these concerns, you can enhance user satisfaction and potentially boost your product’s appeal in the market.

Place Of Purchase – 4

Maintaining brand unity is crucial, especially if you run your e-shop. Harmonizing your cosmetic product packaging design with your brand style ensures a consistent, visually appealing customer experience. Avoid overwhelming customers by ensuring that your product lineup, when displayed together, maintains a cohesive and inviting look.

In contrast, when stocking products in physical stores or supermarkets, a bold and eye-catching design becomes essential. Amidst the competition on a store shelf, your packaging must grab attention swiftly and communicate your product’s essence.

Regardless of the sales platform, compliance with local regulations is paramount. Selling through third-party platforms like Amazon requires strict adherence to their packaging rules as well (Amazon Packaging Certification Guidelines). Considering these aspects in your packaging design strategy is pivotal for success in various sales environments.

Packaging Design – 5

When considering packaging design, it’s not just about the visual appeal; it’s a blend of various elements that make your product stand out. Let’s explore the key aspects to consider when crafting your packaging concept.

Color: Your brand’s color palette is pivotal, but if you’re a startup or struggling with color choices, Pantone’s annual color pick can inspire your packaging design palette. For 2024, Pantone’s ‘Peach Fuzz – Embrace the Warmth’ might spark some fresh ideas.

Copy: Appealing packaging shouldn’t neglect the copy. Keep it concise yet focused on addressing customer pain points.

Shape: Choosing between tubes, bottles, or jars isn’t just about aesthetics; it’s about functionality and experience. Creams and gels suit jars or tubes, while lotions and toners align well with bottles. Consider ease of use; for instance, spatulas for jar creams and avoiding inconvenient bottle caps for lotions.

Budget impacts shape choice; square bottles may cost more to print due to double-sided designs compared to cylinder bottles. Therefore, when deciding on the packaging design, it is necessary to consider the cost of post-processing.

Size: Your packaging’s size not only impacts cost and transportation but also influences packaging hardness and material choices.

Function: Eco-friendly trends favor refillable, recyclable, or multi-use packaging. Ensure your packaging design addresses these aspects in function to align with environmental goals.

Surface Treatment: Consider the texture and visual impact of your packaging. Surface treatments like silk-screen printing or labeling are common. For intricate printing designs, labels may be more practical than silk-screen printing due to cost and technological limitations.

Given the technical aspects involved, discussing ideas with suppliers can streamline your design process and help navigate material and treatment choices more efficiently. This proactive approach minimizes costs and streamlines production.

Packaging Materials – 6

Plastic, glass, and aluminum stand out as the primary materials in contemporary cosmetic and beauty packaging. The sustainability trend prompts brands to explore bio-based materials or 100% PCR options, albeit with limitations on surface treatment techniques and relatively higher costs compared to conventional plastic packaging.

Plastic – 6.1

A plethora of plastics—over 300 types—exist, with about 10 commonly used in cosmetic packaging: ABS, AS, PE (HDPE), PP, PS, PC, PET, PETG, PMMA (Acrylic), and PCR. Selecting the right material entails understanding plastic characteristics and collaborating with suppliers.

At PAGpackaging, we provide professional material solutions, offer free samples for user experience and compatibility testing, and assist in choosing your ideal packaging material.

Glass – 6.2

Glass exudes luxury and quality, particularly for high-end products. Its chemical stability and resistance to high temperatures ensure minimal chemical reactions with contents. However, with glass, consider surface treatment carefully—common techniques like silk-screen printing may face challenges, especially with large color block printing and eco-friendly color paint on glass bottles. Before determining the packaging design, it is best to obtain professional advice from the supplier on surface treatment performance.

Aluminum – 6.3

Lightweight and durable, aluminum offers unique visual effects and eye-catching appearances and is often used for sunscreen lotions or powder compacts. However, it’s essential to note that aluminum isn’t suitable for highly acidic or alkaline products due to potential chemical reactions.

For further information on these common materials or specialized packaging materials, such as bamboo, kraft paper, or sugar cane, visit our website’s ‘Material‘ section or consult with our experts!

Sustainability – 7

In recent years, the environmental impact of non-degradable plastic packaging has become a pressing concern highlighted in the sustainable development agendas of major global fashion companies.

Numerous brands, including beauty care giants like L’Oreal, Unilever, and Procter & Gamble, have prioritized ‘plastic reduction’ in their packaging strategies. They’ve explored innovative solutions such as bio-based plastic recycling, eco-friendly material alternatives, loop packaging, and distribution to address this challenge.

For startups seeking to align with environmentally friendly practices to bolster brand image and resonate with consumers, here are four key areas to focus on:

Embrace Sustainable Packaging Materials – 7.1

Certain plastics like PET, PE, HDPE, PLA, and PBS, due to their performance, production process, environmental impact, and high recycling rates, are considered sustainable options in the cosmetics market.

Some companies invest resources in developing new packaging materials; for instance, L’Oreal collaborates with suppliers to pioneer paper-based cosmetic tubes, reducing plastic content by 45%.

Simplify Packaging Design – 7.2

Recycling cosmetic packaging involves collection, sorting, cleaning, and reprocessing. Simplifying packaging design by avoiding complex or contaminated elements such as difficult-to-clean label layers contributes to sustainability efforts, making recycling more feasible.

Educate Consumers on Recycling – 7.3

Educational marketing initiatives can enlighten users about cosmetic packaging materials and encourage correct disposal practices. Proper storage of empty bottles in suitable environments, away from high temperatures or humidity, prevents the release of harmful chemicals and maintains bottle quality, extending their lifespan.

Implement Bottle Recycling Programs – 7.4

Collaborate with local recycling enterprises to collect waste packaging for recycling. Consider partnerships with packaging manufacturers or suppliers to incorporate more recycled materials into your packaging, contributing to a more sustainable cycle.

For guidance on sustainable materials or packaging solutions, explore our blog or access knowledge resources under the ‘Sustainability’ menu. Feel free to reach out; we’re dedicated to assisting you with sustainable packaging endeavors!

Supplier Reliability – 8

Ensuring the reliability of a supplier is crucial when selecting partners for your business. While platforms like Google and social media like Facebook, and Instagram provide insights into a company’s reputation, assessing reliability goes beyond online reviews.

Look for companies that offer transparent information on their official websites. At PAGpackaging, we prioritize transparency and reliability in our communication. While our website may be relatively new, our commitment to excellence and quality in cosmetic packaging spans years of industry expertise.

When evaluating a supplier’s reliability, consider their responsiveness and willingness to engage with potential clients. Furthermore, seek suppliers who demonstrate expertise through insightful content and industry knowledge.

Our blog and resources aim to educate and assist businesses in navigating the complexities of cosmetic packaging, offering practical insights into sustainable materials, innovative designs, and regulatory compliance. Feel free to follow us and learn more about cosmetic packaging!

MOQ & Cost – 9

When buying cosmetic packaging, many prefer suppliers with flexible Minimum Order Quantity (MOQ) to manage production costs effectively.

Currently, there are two primary sources for low MOQ suppliers: local wholesale suppliers and manufacturers with stock. Stock suppliers usually offer unprocessed packaging, necessitating secondary labeling or screen printing by brands.

For products with minimal packaging requirements and constrained budgets, opting for stock is often a smarter choice. However, categorizing low MOQ suppliers as ‘cost-effective’ can be misleading, considering the hidden expenses commonly associated with the procurement process.

The typical costs in packaging selection include raw material procurement, production techniques, customization expenses, transportation, logistics, and quality checks. Yet, several hidden costs tend to slip under the radar, such as inventory management, quality control, and environmental considerations, among others.

Excessive inventory ties up funds and accrues storage fees, while insufficient stock might drive up purchase prices due to urgency. Quality issues with packaging necessitate additional time and money for returns, potentially impacting customer satisfaction negatively.

Environmental consciousness and sustainable materials might initially raise production costs but can yield long-term brand image benefits. Therefore, when assessing overall costs, allocating a portion of your budget as a buffer for unforeseen expenses is crucial, rather than focusing solely on the expenditure amount.

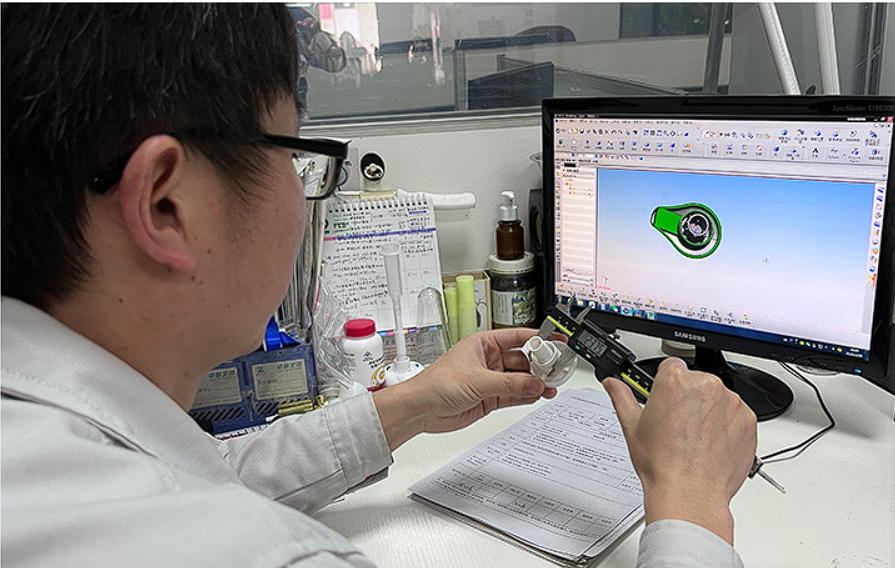

Sample Quality – 10

Assessing sample quality stands as a pivotal measure in gauging a supplier’s production capability and sets the benchmark for subsequent large-scale production quality.

Factories typically conduct tests on their packaging products, yet it’s crucial for brands to independently verify samples received to ensure they align with user experience standards.

Referencing our article ‘Packaging Inspection Ultimate Guidelines’ can offer insights into common defects found in various packaging materials. This resource provides detailed testing directions and methods. Alternatively, engaging a third-party professional organization for specific sample property testing can offer an additional layer of assurance.

Mass Production Defective Rate – 11

While a perfect sample reflects quality, it doesn’t guarantee flawless mass production. In this phase, occasional imperfections are inevitable due to the intricate nature of cosmetic packaging manufacturing. Machinery and production processes, while advanced, still require manual adjustment of relevant parameters.

Quality control processes are integral to minimizing defects during mass production, aiming to maintain a defective rate within 5%~10%, a standard embraced by most factories. This will depend on the choice of packaging materials and the complexity of the design.

Consistency within a production batch is generally maintained in terms of product quality and attributes. However, variations in color and hardness across different batches are common due to manual color formula adjustments and parameter fine-tuning in production. Acceptable industry norms consider an error rate within ±5% as normal.

Extra Packaging – 12

Glass and plastic bottles undergo different packaging processes before delivery. Conventional glass bottles with decorative finishes are usually individually packed in PE bags and then placed in cartons with baffles for added protection.

In contrast, plastic bottles are generally not double-bagged upon delivery. However, for brands concerned about the bottle’s decoration being affected by transit turbulence, double-bagging plastic bottles might be an option to prevent friction that could damage the printing.

Secondary packaging considerations go beyond just cost and environmental concerns; they also impact convenience and efficiency during bulk canning operations.

For instance, in canning factories, manual bottle handling during material filling is common. Secondary packagings like PP bagging or PE foam grids assures bottle integrity and process safety. However, such packaging significantly reduces canning efficiency.

Automatic filling machines cannot utilize these methods for secondary packaging as they cannot grasp glass bottles. Instead, customizing alternative packaging to protect glass bottles while facilitating automatic machine grasping becomes necessary.

Production Lead Time – 13

The typical delivery time for custom cosmetic packaging from China falls within the range of 30 to 60 days. Several factors influence this timeline, including the supplier’s production cycle, order volume, raw material availability, production equipment conditions, and chosen transportation mode.

To ensure seamless planning and avoid potential delays, it’s advisable to plan cosmetic packaging purchases well in advance. This proactive approach helps mitigate longer delivery periods caused by various factors such as heightened seasonal demand, increased factory orders, or shipping disruptions due to extreme weather conditions. This foresight safeguards the product’s marketing plan from potential setbacks.